Category: Articles

Articles written by members, including technical articles or advice.

-

-

Designing an Amateur Radio Antenna Installation using a Tailored Commercial System Engineering Process

Designing an Amateur Radio Antenna Installation using a Tailored Commercial System Engineering Process

Stephen P. Johnson, D.Sc. N2FTWhen I moved into my current home twenty years ago in a community with a homeowner association (HOA), I knew that setting up an effective antenna system that would not arouse the ire of the architecture review board would be a challenge. I operated mobile on VHF and HF for many years and operated a low “inverted vee” in the backyard for a while, but convenience and performance were lacking. I primarily wanted to operate HF DX contests from home and make reasonable numbers of contacts.

In my job as a professional system engineer and systems architect with the Raytheon Company (now retired), I was periodically called upon to help envision and design complex systems to meet challenging customer requirements. My company has developed and comprehensively applies a thorough systems engineering process defined by an Integrated Product Development System – a collection of business processes and tools that Raytheon uses throughout the product lifecycle. This system is applied to the complex task of satisfying customer needs with optimized system designs.

Faced with the need for a custom antenna system for my home amateur station, I decided to leverage my professional systems engineering background and apply some of the engineering analysis and design techniques I have used at work to design an antenna system that would be reasonably low profile yet provide adequate performance. Although this antenna design may provide the basis for others to build similar antenna systems through replication or adaptation, the primary thrust of this article is to present a simplified system engineering approach and the problem solving techniques I used so the reader can understand the overall thought process and then apply similar methods to solve their own amateur radio system design problems. It should be noted that I am not a professional RF engineer, so I approach this job with the RF technical skills of a typical technically-oriented amateur operator.

Please see Stephen’s full article – Designing an Amateur Radio Antenna Installation using a Tailored Commercial System Engineering Process

-

A Tri-Band Parasitic, Portable Vertical Array

2024 ARRL Antenna Design Submission for 80-10 meter Category

A Tri-Band Parasitic, Portable Vertical Array

Stephen P. Johnson D.Sc. (N2FT)

and

Thomas H. Schiller (N6BT)

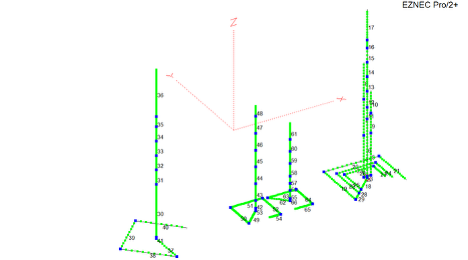

The subject of this submission is a portable tri-band parasitic vertical array designed for locations with limited space and time. The array uses a single ¼ wave multi-band driver and three single-band reflectors to provide low-angle gain on 20, 15, and 10 meters. It supports operations in N2FT’s HOA-controlled environment by providing a relatively low-profile design that can be quickly installed for the duration of a contest and then stored. This specific implementation was designed by N2FT based on the many technical innovations developed by his friend and antenna Elmer, N6BT.

Tom Schiller, N6BT, has been building parasitic vertical arrays for DX contests and DX expeditions for decades. They are described in his superb book, “Array of Light”, which is now in its fourth edition [1]. Tom’s early successful efforts for Team Vertical (co-founded by Kenny Silverman, K2KW) featured single-band, two element vertical parasitic arrays using two elevated gull-wing radials. He also paralleled two of these arrays for greater gain. Tom later developed the commercial Sigma product line utilizing a compressed vertical dipole capacity loaded on the top and bottom (imagine a large letter “I”), then a simplified, bottom-fed design, the Bravo series, which only utilized bottom capacity loading. Both of these designs were single and multi-band using either manual length changes, or relay-controlled inductors at the feed points. He continued research and eventually developed the vertical-open-ring (VOR) design used on this project: an open ring counterpoise for verticals that replaces the elevated radials with roughly equivalent performance and requires minimal space. Finally, Tom discovered that by using concentric rings for each band of interest, he could operate on multiple bands with an adjustable vertical (i.e., SteppIR).

The fan dipole has been a well-known amateur multi-band antenna design for even longer. It is unclear when the idea was first applied to multiband vertical antennas, but Callum, M0MCX, has done a great deal to popularize the multiband fan vertical using wire elements with his DX Commander offering [2]. N2FT applied these design ideas using aluminum tubing elements to achieve tri-band operation.

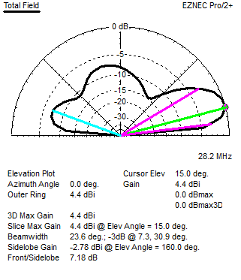

The antenna described in this submission for 20,15, and 10 meters, combines N6BT’s concentric open ring counterpoise, a variant of the fan vertical, aluminum tubing radiators, and movable supports to produce an array that is portable. It provides about 4dB of gain at low elevation angles. The “beam” can be rotated by picking up and moving a reflector using the “Arm-strong” method. It has low visibility from the street in N2FT’s backyard and is installed for contest weekends and then stored to reduce the chance of HOA intervention. N2FT has used the antenna successfully in numerous DX contests. The antenna would also be suitable for POTA (but probably not SOTA) activations. It is likely a lower weight variant could be easily designed and constructed.

This implementation was developed using surplus aluminum antenna parts donated by generous members of N2FT’s contesting club (Potomac Valley Radio Club). N2FT modeled the design using NEC-5, EZNEC, and AutoEZ. The design can be implemented as is, but there are other potential implementations that can be implemented using materials from the individual ham’s junk-box. This would require adjusting the EZNEC model to reflect different radiator diameters or materials. NEC-5 is recommended due to its ability to model closely spaced wires. NEC-2 gives different and often less reliable results.

N2FT would like to underscore his gratitude to N6BT for his inspiration, kind mentorship, and for being the best Antenna Elmer any OM could want.

Many thanks to Dan McGuire (AC6LA) for his excellent AutoEZ EZNEC optimization tool and for priceless and incredibly responsive help with the AutoEZ optimizer set-up and array optimization. Thanks also to LLNL for developing the NEC antenna modeling tool, and to Roy Lewallen (N7EL) for developing EZNEC and his contributions to the antenna modeling community.

The Array

The array consists of the tri-band driver and a separate reflector for each band. Due to the proximity of the 10 meter and 15-meter counterpoises, there is some noticeable coupling between them, and the orientation of the rings shown seems to minimize the coupling. See the attached wires list for “wire” lengths and diameters.

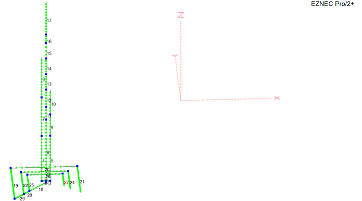

The Driver

Driver Ring Supports and Radiator Support

The driver uses three concentric open rings for the counterpoise and three parallel radiators made from aluminum tubing. The base of the radiators is an aluminum member cut from surplus aluminum stock using a carbide-tipped blade on a table saw and drilled slightly smaller than the element diameters. Non-conductive material could be used, but then wires would be required to connect each of the vertical radiators, and the EZNEC model would require adjustment. This member supports the radiators and provides for a tight fit and electrical connectivity when the halves are bolted together. The radiators are separated and reinforced by an acrylic spacer about 4 feet up (non-critical). The 20-meter radiator is centrally placed and the 10 and 15-meter radiators are offset about 6” to either side. This order may not be optimal; an alternative would be to place the 20-meter and 10-meter radiators on the ends to minimize coupling between these harmonically related bands. Changing the order would require adjustments to the EZNEC model due to the element’s interactions.

PVC 5-way connectors (1”) are drilled out to become 6-way connectors to support the rings. The ring supports in one implementation are 3/4” PVC pipe. Other mechanical arrangements have been tried to reduce the 1” diameter mounting hole to use commonly available 3/8” fiberglass rod. None of the adaptations have been fully satisfactory. An alternative would be to use a piece of solid material drilled out for the 3/8” rods and the vertical support, and the next version of the antenna will likely use this approach.

The shared first side of the driver’s three concentric rings is made from aluminum tubing to handle the relatively high current near the feed point. N6BT discovered that this provides slightly less loss than an all-wire implementation. The remainder of each ring is made from 12 AWG PVC insulated wire.

The driver and 20-meter reflector are supported by tripods that were on hand. Fiberglass tubing from reused quad spreader sections and fiberglass tubing sections purchased from Max Gain Systems was used to insulate the radiating elements and counterpoise from the tripod. The driver is fine-tuned for SWR after the reflectors are installed. The tripod is normally staked down and guyed to prevent the driver from blowing over in high winds. This occurred once before the tripods were staked down, and it resulted in damage to the PVC 6-way coupler.

The model was designed to match the currents into the radiator and counterpoise as closely as possible to maximize emission by the vertical radiator, minimize common-mode current on the feedline and the consequent balun heating. A choke balun is used on the feedline to reduce unwanted radiation by the feedline.

Example Adaptation of 1” PVC 6-way to host 3/8” fiberglass rod with Reflector Jumper

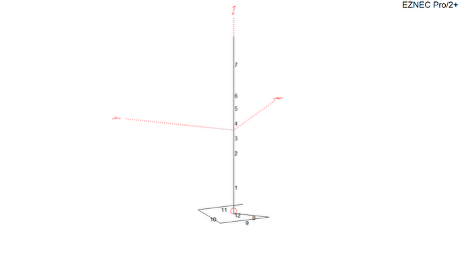

The Reflectors

The reflectors are simpler versions of the driver, consisting of one vertical radiator and one ring. The 20-meter reflector was implemented to be supported by a tripod identical to the driver. The other reflectors are supported by sections of old fiberglass quad spreaders that were in the junk-box. The 15-meter and 10-meter reflectors are held up by patio umbrella stands commonly available online. The 20-meter reflector and driver could also be implemented using this approach, but careful staking of the stands and guys would be required to survive high winds. Each radiator includes a jumper with an alligator clip that connects the radiator and counterpoise in normal operation. This jumper is easily detached to disable the reflector. This allows the array to be used in omnidirectional mode for that band, e.g., to work South America while the array is pointed towards Europe. This has proven to be a handy feature. If greater gain is needed in another direction (e.g., for working JA after Europe closes), the reflector can be picked up and moved to steer the beam for that direction.

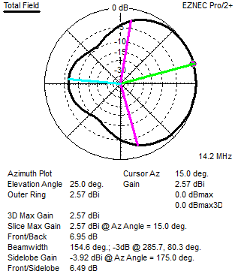

20 Meter Array Patterns from Model

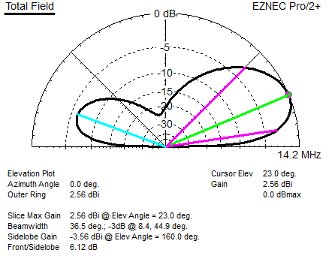

15 Meter Array Patterns from Model

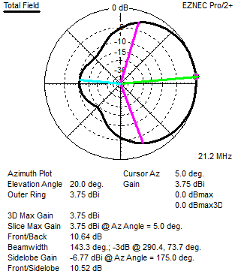

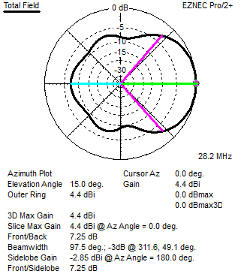

10 Meter Array Patterns from Model

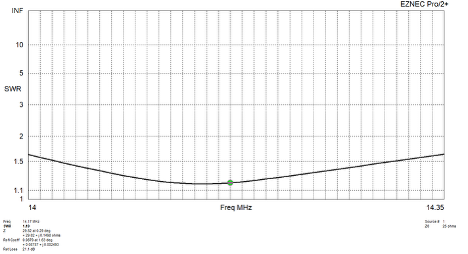

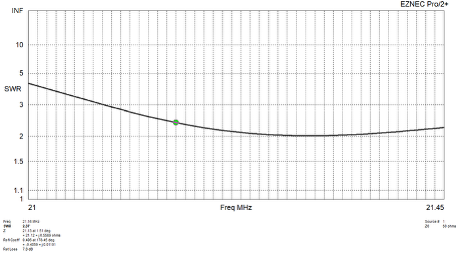

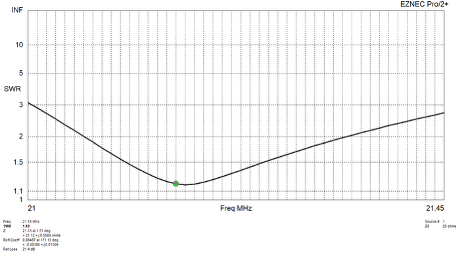

SWR from Model and Measurements

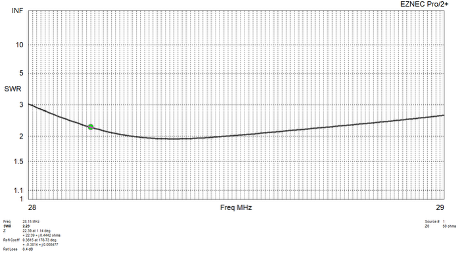

20 Meter SWR into 50 Ohm Feedline

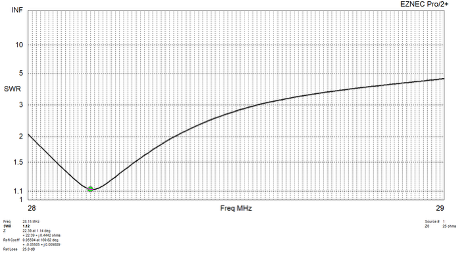

20 Meter SWR into 1:2 UNUN

Hairpin matches are frequently used for single-band antennas to match lower impedances to 50-ohm feedlines. In this case, a 1:2 UNUN was used to achieve results that would apply to all three bands of interest.

As Built SWR Measured at Antenna (at 50 ohms)

Measurements were made using a Rig Expert A-55 Zoom calibrated with the reference plane at the antenna. No 1:2 UNUN was used for as-built measurement. All the as-built SWR measurements were made before the latest model optimization, but any changes to these measurements are expected to be minimal based on previous similar design iterations.

Frequency SWR 14.0 1.9 14.1 1.6 14.2 1.4 14.3 1.4 14.35 1.4 15 Meter SWR into 50 Ohm Feedline

15 Meter SWR into 1:2 UNUN

As Built SWR Measured at Antenna (measured at 50 ohms)

Frequency SWR 21.0 2.8 21.1 2.2 21.2 1.7 21.3 1.4 21.4 1.4 21.45 1.4 10 Meter SWR into 50-ohm Feedline

10 Meter SWR into 1:2 UNUN

10m SWR Measured from As-Built Antenna (at 50 ohms)

As Built SWR Measured at antenna

Frequency SWR 28.0 3.0 28.2 2.7 28.4 2.1 28.6 1.8 28.8 1.6 29.0 1.7 29.2 1.9 Bill of Materials

Because this antenna was built using materials from N2FT’s junk box, it is unlikely that any subsequent version would or should be implemented the same way.

For this reason, in addition to the EZNEC wires list is given to provide the lengths and diameters of each of the radiating elements, a notional bill of materials is also provided with some design alternatives.

- Driver and Reflectors

- Driver or Reflector base (tripod, umbrella stand, stake in ground)

- Driver support (non-conducting) – insulating tubing (fiberglass, PVC), guy ropes, stakes for base

- Radiator support (member to hold three radiators) – aluminum, black Delrin, HDPE, etc)

- Radiator Spacing – nonconducting member to reinforce and support radiators

- Aluminum tubing for radiators

- Stainless Hose clamps or other means to join radiator sections

- Aluminum tubing for first segment of concentric rings

- Wire for the remainder of concentric rings.

- Insulators for ring ends

- Terminals, stainless hardware

EZNEC Pro/2+ ver. 7.0 Tribander with open ring 12/16/2024 12:24:15 PM --------------- WIRES --------------- No. End 1 Coord. (in) End 2 Coord. (in) Dia (in) Segs Insulation Wire Loss Conn. X Y Z Conn. X Y Z Diel C Thk(in) Cond(S/m) Perm 1 W18E1 264.9, 0, 68 W2E2 264.9, 0, 70 0.875 2 1 0 4E-08 1 2 W4E1 260.4, 0, 70 W3E1 264.9, 0, 70 0.875 3 1 0 4E-08 1 3 W6E1 264.9, 0, 70 W5E1 269.4, 0, 70 0.875 3 1 0 4E-08 1 4 W2E1 260.4, 0, 70 W7E1 260.4, 0, 122.5 0.875 14 1 0 4E-08 1 5 W3E2 269.4, 0, 70 W9E1 269.4, 0, 122.5 0.875 14 1 0 4E-08 1 6 W1E2 264.9, 0, 70 W11E1 264.9, 0, 141.5 1.125 19 1 0 4E-08 1 7 W4E2 260.4, 0, 122.5 W8E1 260.4, 0, 167.5 0.63 12 1 0 4E-08 1 8 W7E2 260.4, 0, 167.5 260.4, 0, 214.5 0.375 13 1 0 4E-08 1 9 W5E2 269.4, 0, 122.5 W10E1 269.4, 0, 147.5 0.63 7 1 0 4E-08 1 10 W9E2 269.4, 0, 147.5 269.4, 0, 176.5 0.44 8 1 0 4E-08 1 11 W6E2 264.9, 0, 141.5 W12E1 264.9, 0, 156.25 1.1 4 1 0 4E-08 1 12 W11E2 264.9, 0, 156.25 W13E1 264.9, 0, 176.5 1 6 1 0 4E-08 1 13 W12E2 264.9, 0, 176.5 W14E1 264.9, 0, 194.5 0.875 6 1 0 4E-08 1 14 W13E2 264.9, 0, 194.5 W15E1 264.9, 0,212.625 0.75 6 1 0 4E-08 1 15 W14E2 264.9, 0,212.625 W16E1 264.9, 0,230.625 0.625 4 1 0 4E-08 1 16 W15E2 264.9, 0,230.625 W17E1 264.9, 0, 240.75 0.5 4 1 0 4E-08 1 17 W16E2 264.9, 0, 240.75 264.9, 0, 279.5 0.375 12 1 0 4E-08 1 18 W1E1 264.9, 0, 68 W25E1 246.5, -18.4, 68 0.75 8 1 0 4E-08 1 19 W29E2 230.3, -34.6, 68 W20E1 230.3, 34.6, 68 #12 20 1 0 4E-08 1 20 W19E2 230.3, 34.6, 68 W21E1 299.5, 34.6, 68 #12 12 1 0 4E-08 1 21 W20E2 299.5, 34.6, 68 299.5, -25.5, 68 #12 16 1 0 4E-08 1 22 W28E2 240.5, -24.4, 68 W23E1 240.5, 24.4, 68 #12 13 1 0 4E-08 1 23 W22E2 240.5, 24.4, 68 W24E1 289.3, 24.4, 68 #12 13 1 0 4E-08 1 24 W23E2 289.3, 24.4, 68 289.3, -14.5, 68 #12 12 1 0 4E-08 1 25 W28E1 246.5, -18.4, 68 W26E1 246.5, 18.4, 68 #12 10 1 0 4E-08 1 26 W25E2 246.5, 18.4, 68 W27E1 283.3, 18.4, 68 #12 10 1 0 4E-08 1 27 W26E2 283.3, 18.4, 68 283.3, -9, 68 #12 10 1 0 4E-08 1 28 W18E2 246.5, -18.4, 68 W29E1 240.5, -24.4, 68 0.75 3 1 0 4E-08 1 29 W22E1 240.5, -24.4, 68 W19E1 230.3, -34.6, 68 0.75 5 1 0 4E-08 1 30 W41E2 0, 0, 70 W31E1 0, 0, 136 1.125 34 1 0 4E-08 1 31 W30E2 0, 0, 136 W32E1 0, 0, 154.25 1 10 1 0 4E-08 1 32 W31E2 0, 0, 154.25 W33E1 0, 0, 172.25 0.875 10 1 0 4E-08 1 33 W32E2 0, 0, 172.25 W34E1 0, 0,190.375 0.75 10 1 0 4E-08 1 34 W33E2 0, 0,190.375 W35E1 0, 0,208.375 0.625 10 1 0 4E-08 1 35 W34E2 0, 0,208.375 W36E1 0, 0, 221 0.5 7 1 0 4E-08 1 36 W35E2 0, 0, 221 0, 0, 281.6 0.375 40 1 0 4E-08 1 37 W41E1 0, 0, 68 W38E2 0, -45, 68 0.064 10 1 0 4E-08 1 38 W39E1 -45, 0, 68 W37E2 0, -45, 68 0.064 10 1 0 4E-08 1 39 W38E1 -45, 0, 68 W40E2 0, 45, 68 0.064 10 1 0 4E-08 1 40 41, 4, 68 W39E2 0, 45, 68 0.064 10 1 0 4E-08 1 41 W37E1 0, 0, 68 W30E1 0, 0, 70 0.064 2 1 0 4E-08 1 42 W53E2 124.7, 0, 70 W43E1 124.7, 0, 80 1.125 10 1 0 4E-08 1 43 W42E2 124.7, 0, 80 W44E1 124.7, 0, 101 1 10 1 0 4E-08 1 44 W43E2 124.7, 0, 101 W45E1 124.7, 0, 122 0.875 10 1 0 4E-08 1 45 W44E2 124.7, 0, 122 W46E1 124.7, 0, 143 0.75 10 1 0 4E-08 1 46 W45E2 124.7, 0, 143 W47E1 124.7, 0, 164 0.625 10 1 0 4E-08 1 47 W46E2 124.7, 0, 164 W48E1 124.7, 0, 185.5 0.5 10 1 0 4E-08 1 48 W47E2 124.7, 0, 185.5 124.7, 0, 199.7 0.375 10 1 0 4E-08 1 49 W53E1 124.7, 0, 67 W50E1 104.7, -20, 67 #12 24 1 0 4E-08 1 50 W49E2 104.7, -20, 67 W51E1 104.7, 20, 67 #12 30 1 0 4E-08 1 51 W50E2 104.7, 20, 67 W52E1 144.7, 20, 67 #12 30 1 0 4E-08 1 52 W51E2 144.7, 20, 67 W54E1 144.7, -20, 67 #12 20 1 0 4E-08 1 53 W49E1 124.7, 0, 67 W42E1 124.7, 0, 70 #12 2 1 0 4E-08 1 54 W52E2 144.7, -20, 67 130.2, -20, 67 #12 30 1 0 4E-08 1 55 W66E2 168, 0, 70 W56E1 168, 0, 80 1.125 10 1 0 4E-08 1 56 W55E2 168, 0, 80 W57E1 168, 0, 89 1 10 1 0 4E-08 1 57 W56E2 168, 0, 89 W58E1 168, 0, 98 0.875 10 1 0 4E-08 1 58 W57E2 168, 0, 98 W59E1 168, 0, 114 0.75 10 1 0 4E-08 1 59 W58E2 168, 0, 114 W60E1 168, 0, 129 0.625 10 1 0 4E-08 1 60 W59E2 168, 0, 129 W61E1 168, 0, 144 0.5 20 1 0 4E-08 1 61 W60E2 168, 0, 144 168, 0, 165.2 0.375 20 1 0 4E-08 1 62 W66E1 168, 0, 67 W63E1 150, 18, 67 #12 10 1 0 4E-08 1 63 W62E2 150, 18, 67 W64E1 186, 18, 67 #12 20 1 0 4E-08 1 64 W63E2 186, 18, 67 W65E1 186, -18, 67 #12 20 1 0 4E-08 1 65 W64E2 186, -18, 67 162.6, -18, 67 #12 20 1 0 4E-08 1 66 W62E1 168, 0, 67 W55E1 168, 0, 70 #12 10 1 0 4E-08 1

References

- Thomas H. Schiller (N6BT), Array of Light, Fourth Edition. Published by the author; Founder, Force 12, Inc.; Next Generation Antennas; Antenna Airborne Research, Inc.

- Callum, M0MCX, dxcommander.com